Voltage Optimisation for Business

What is Voltage Optimisation?

The concept behind voltage optimisation is simple. In general, power from the National Grid is supplied at a higher voltage than necessary due to old electrical distribution networks in place which were designed to operate at higher voltage levels, as well as electricity suppliers being required to ensure all buildings are supplied voltage within set parameters.

If a building is being supplied at a higher voltage than necessary it will likely result in a mass of wasted energy, excessive levels of carbon emissions, and higher than necessary electricity bills in addition to power quality issues, including increased wear and reduced lifespan of electrical equipment.

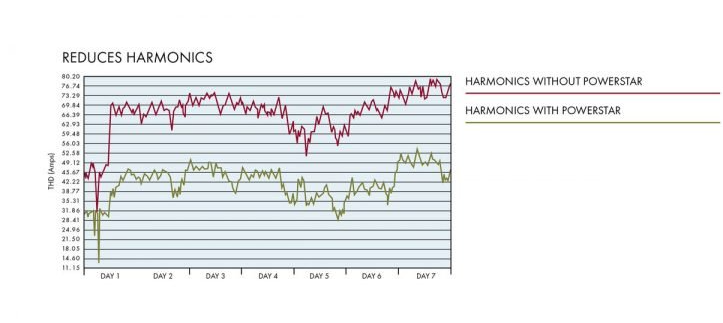

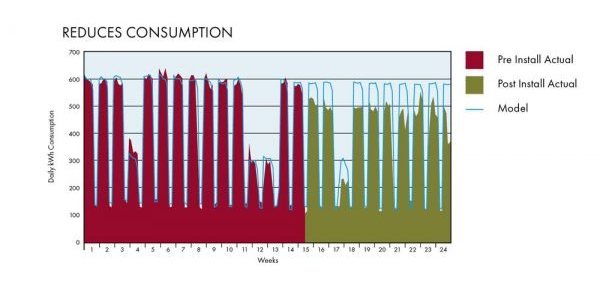

In addition to reducing energy consumption, cutting carbon emissions and providing savings on electricity bills, voltage optimisation can also improve power quality by balancing phase voltages and filtering harmonics and transients from the network operators supply.

Voltage optimisation technologies are typically installed in series between the distribution transformer and the main low voltage distribution board, allowing all of the consumer’s electrical equipment to benefit from an optimised power supply.

What’s the payback for Voltage Optimisation?

Typically a voltage optimiser will pay for itself in around 3-4 years (under 2 with an energy saving grant), the payback period is dependent on the types of equipment installed and the incoming voltage to the site, the higher the voltage the quicker the payback. The manufacturers will carry out a detailed energy assessment of the site and issue a proposal which they will back up with a guarantee of the savings that will be achieved, if for any reason there’s a shortfall in energy savings from the proposal they’ll issue a cheque for the difference!

What types of equipment benefit most from Voltage Optimisation?

Any equipment that uses an electric motor such as refrigeration, heat pumps, conveyor belts, ventilation fans and presses will benefit greatly from running at the optimal voltage. Energy savings of up to 15% on this type of equipment are achievable as well as prolonging their life and reducing servicing requirements. Computer equipment such as servers, PC’s and monitors all have inductive loads so will consume less energy and work more efficiently.

What types of Voltage Optimisers are available?

There are both high voltage and low voltage systems available which will sit either side of the sites transformers, a site survey will determine the most suitable application. There are fixed voltage reduction systems ie for sites that have a stable incoming voltage the optimiser will reduce the supply by a fixed amount, and there are dynamic systems which constantly monitor the incoming supply and reduce the voltage to a predetermined level.